Research Institute,Baoshan Iron & Steel Co.,Ltd.,Shanghai 201999,China

Abstract: This paper explores the development of a 780 MPa hot-rolled high-strength steel with an ultra-high hole expansion ratio (HER) by using a nanoprecipitation-controlled technology.Systematic analysis and evaluation of an industrially produced steel sheet have been performed to investigate the microstructure,nanoprecipitates,tensile properties,HER,bendability,and forming limit diagram.The newly developed 780 MPa hot-rolled high-strength steel sheet is composed of a fully ferritic microstructure of approximately 5 μm with precipitates of approximately 4-5 nm in ferrite grain interiors.The yield strength and tensile strength can reach above 700 and 780 MPa,respectively.Moreover,the fractured elongation is higher than 19% in the transversal direction,and the average HER exceeds 70%.Furthermore,the newly developed 780 MPa high-strength steel has good bendability reaching R/t=0.2 at 90°.Compared with the conventional 780 MPa high-strength steel,the newly developed 780 MPa high-strength steel exhibits superior forming ability,which is suitable for the production of complex components.High-cycle fatigue indicates that the fatigue limit of the newly developed high-strength steel is 430 MPa under a stress ratio of r=-1,indicating good fatigue properties.The excellent combined mechanical properties of the newly developed 780 MPa high-strength steel are attributed to the grain-refined ferritic microstructure with nanoprecipitates in ferrite grain interiors.

Key words: nanoprecipitation; fully ferritic steel; hole expansion ratio (HER); fatigue limit; forming limit diagram (FLD)

Strong carbide-forming elements such as Nb,Ti,and V can form dispersedly distributed nanoparticles in the form of interphase or random precipitation in the ferritic matrix,with an average size smaller than 10 nm.This interphase or random nanoprecipitate can strongly inhibit the movement of dislocations,thereby increasing strength.In recent years,the nano-precipitation phenomenon in ferrite has received con-siderable attention because of its high ductility,high hole expansion ratio (HER),and good surface quality(red scale-free).Many investigators have con-ducted several studies to clarify the formation mech-anism of nanoprecipitation,particularly interphase precipitation.For example,FUNAKAWA et al.[1]studied interphase precipitation in a Ti-Mo system and found that the size of precipitates was 3 nm,and the ferrite grain size was approximately 3.1 μm.These interphase nanoprecipitates in ferrite grains contribute approximately 300 MPa to the strength.By controlling interphase precipitation,SETO et al.[2]developed a new 780 MPa hot-rolled high-strength steel with higher HER and fatigue limit than con-ventional high-strength silicon-bearing steels.The refined single-phase ferritic microstructure and nano-sized interphase precipitates are responsible for the high ductility,high HER,and high fatigue limit.

More studies have focused on the formation mechanism of interphase precipitation during the transformation from austenite to ferrite.OKAMOTO et al.[3]investigated interphase precipitation in Nb-microalloyed steel and observed that interphase pre-cipitation occurred after 10 s isothermal holding at 650-750 ℃.The dominant interphase precipitates are planar type,whereas non-planar type is often observed,particularly near the grain boundary.YEN et al.[4]conducted a systematic study of the inter-phase precipitation in Ti-Mo steel at 630-720 ℃ after 30 s isothermal transformation.Therefore,the development of interphase-precipitated carbides is associated with the growth of the incoherent ferrite/austenite interface by the ledge mechanism.In addition,the contribution of interphase precipitation hardening to the yield strength of steel is based on the classical Orowan mechanism.That is,except for the size and volume fraction of precipitates,sheet spacing and intercarbide spacing of precipitates play a decisive role in strengthening the ferritic matrix.Later,Yang’s group further studied interphase pre-cipitation at 620-700 ℃ during continuous cool-ing.The results showed that randomly homogeneous precipitation carbides and interphase precipitation carbides coexisted in the ferritic matrix,which led to non-uniform mechanical properties of individual ferrite grains[5].

Based on the abovementioned studies,interphase precipitation usually occurs at a relatively higher temperature range (e.g.,620-720 ℃),which can be used to strengthen the single-phase ferritic matrix.The uniformed single-phase ferritic micro-structure and dispersed nanoprecipitates will result in high ductility,ultra-high HER,high surface quality,and high fatigue,thereby limiting the app-lication of a new type of hot-rolled advanced high-strength steel sheet.Based on this concept and previous laboratory studies,Baosteel successfully deve-loped a new type of 780 MPa hot-rolled advanced high-strength steel with excellent surface quality,high ductility,ultra-high HER,and high fatigue limit.Furthermore,the newly developed 780 MPa hot-rolled high-strength steel will be introduced in great detail.

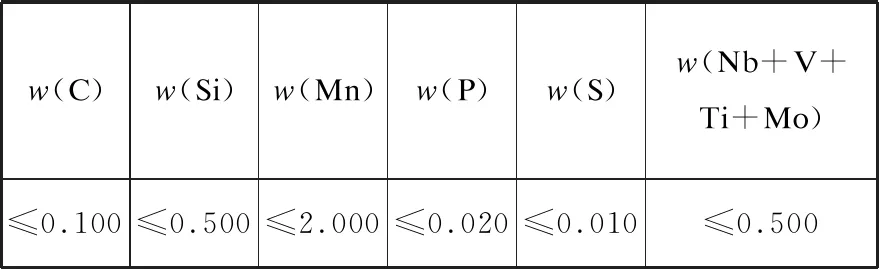

The chemical composition of the industrially produced hot-rolled steel sheet is shown in Table 1.A small amount of microalloying elements were added to the base of low-C-Mn composition to increase the strength of steel by precipitation strengthening.The total amount of microalloying elements such as Nb,Ti,V,and Mo is lower than or equal to 0.5%.Hot rolling is systematically described as follows.A high furnace temperature of over 1 200 ℃ is neces-sary to completely dissolve the coarse precipitates that exist in the steel billet formed during contin-uous casting.Rough and finish rolling should be per-formed at a relatively fast pace to decrease the pre-cipitation in the austenitic region;thus,the precipit-ation in the austenitic region can consume a certain amount of carbon,leading to the decrease in carbon content available in the subsequent ferritic region and deteriorating the precipitation strengthening effect.Coiling temperature is controlled in an app-roximate range to maximize the precipitation streng-thening effect.Therefore,the chemical composition and hot rolling should be precisely controlled to obtain such excellent advanced high-strength steel sheets.

Table 1 Chemical composition of the industrially produced 780 MPa steel %

Transversal tensile specimens were machined from the steel sheet perpendicular to the rolling direction with a gauge length of 50 mm and a gauge width of 25 mm.They were tested using a tensile tester at a strain rate of 10-3s-1at room tempera-ture.Three specimens for hole expansion experi-ments were cut from the steel sheet from 1/4,1/2,and 3/4 width in sequence at each position with a dimension of 100 mm×100 mm.The bending specimen of 30 mm×100 mm perpendicular to the rolling direction was cut from the steel sheet in the 1/4-width position.Six specimens of different sizes ranging from 30 mm×150 mm to 150 mm×150 mm were prepared to measure forming limit dia-gram (FLD).Microstructural observations were carried out by using standard metallurgical grinding and polishing techniques.4% Nital etchant was used to reveal the microstructure.Then,thin foils for transmission electron microscopic (TEM) obser-vations were sliced from the steel sheet and pre-pared by twin-jet electropolishing.TEM obser-vations for nanoprecipitates were performed in a JEOL JEM 2100 transmission electron microscope with an operating voltage of 200 kV.

3.1 Microstructure and precipitates

Fig.1 shows the typical optical micrograph of the newly developed 780 MPa hot-rolled steel sheet with ultra-high HER.The microstructure primarily consists of nearly full ferrite with a small amount of pearlite.This finding indicates that the carbon atoms are almost fixed with microalloying elements to form nanoprecipitates.The ferrite grains are small,with a size of approximately 4 μm.TEM obser-vations were carried out using a typical micrograph to provide insights into nanoprecipitates (Fig.2).Nanoprecipitates with a size of approximately 4-5 nm are formed in ferrite grains,which strongly contribute to the strength of the steel sheet.

Fig.1 Typical microstructure of the industrially produced 780 MPa hot-rolled steel sheet

Based on our thermodynamic model[6],the volume fraction of nanoprecipitates can be precisely calculated on the basis of practical chemical com-position.Determining the average size and volume fraction of the precipitates,we can evaluate the contribution of precipitation strengthening,which is approximately 300-400 MPa.Evidently,nanopre-cipitation strengthening plays an important role in increasing the strength of steel sheets.As shown in Fig.2,the interphase and random precipitation coexist in the steel sheet,and interphase precipitation is predominant.

3.2 Mechanical properties

Table 2 lists the tensile properties and HERs of the newly developed 780 MPa hot-rolled steel sheet at three different positions along the width direction of the outer and inner coil.The yield strength and tensile strength remain almost unchanged,indicating the high property stability in the width direction.Compared with the tensile strength at the outer and inner ring positions,a slight change in yield strength was observed,whereas tensile strength is stable with a maximum deviation of only 26 MPa.This finding suggests good stability in the rolling direction.

Table 2 Mechanical properties of the newly developed 780 MPa hot-rolled steel sheet

In addition,fractured elongation is higher than that of the conventional high-strength steel with a ferrite and bainite microstructure.Notably,fractured elongation and HER are high,which is better than the conventional high-strength steel with high HER.In general,fractured elongation is inversely pro-portional to the HER;that is,the higher the frac-tured elongation,the lower the HER and vice versa.However,using the nanoprecipitation technology,we can develop a new type of advanced high-strength steel with ultra-high HER.For conven-tional 780 MPa high-strength steel,the HER is usually larger than 50%,whereas the newly deve-loped 780 MPa high-strength steel has ultra-high HER with an average HER exceeding 80%,indicating the high strength,high ductility,ultra-high HER,and good surface quality for the newly developed 780 MPa high-strength steel sheet.

3.3 Bendability

A systematic bending test was performed for the newly developed 780 MPa hot-rolled steel sheet perpendicular to the rolling direction under bending conditions ofR/t=0.2,0.4,1.0,and 1.2 and V-type bending angle of 90°,whereRandtrepresent the bending radius and sheet thickness,respectively.Fig.3 exhibits the bent specimen under the four abovementioned conditions.Moreover,no cracks are observed in the maximum bending position.This result indicates that the newly developed 780 MPa hot-rolled steel sheet has excellent bendability,which can be attributed to the high elongation caused by refined,fully ferritic microstructures.

Fig.3 Systematic bending experiments for the newly developed 780 MPa hot-rolled steel sheet with a V-type bending angle of 90° and a sheet thickness of 2.5 mm

3.4 Fatigue limit

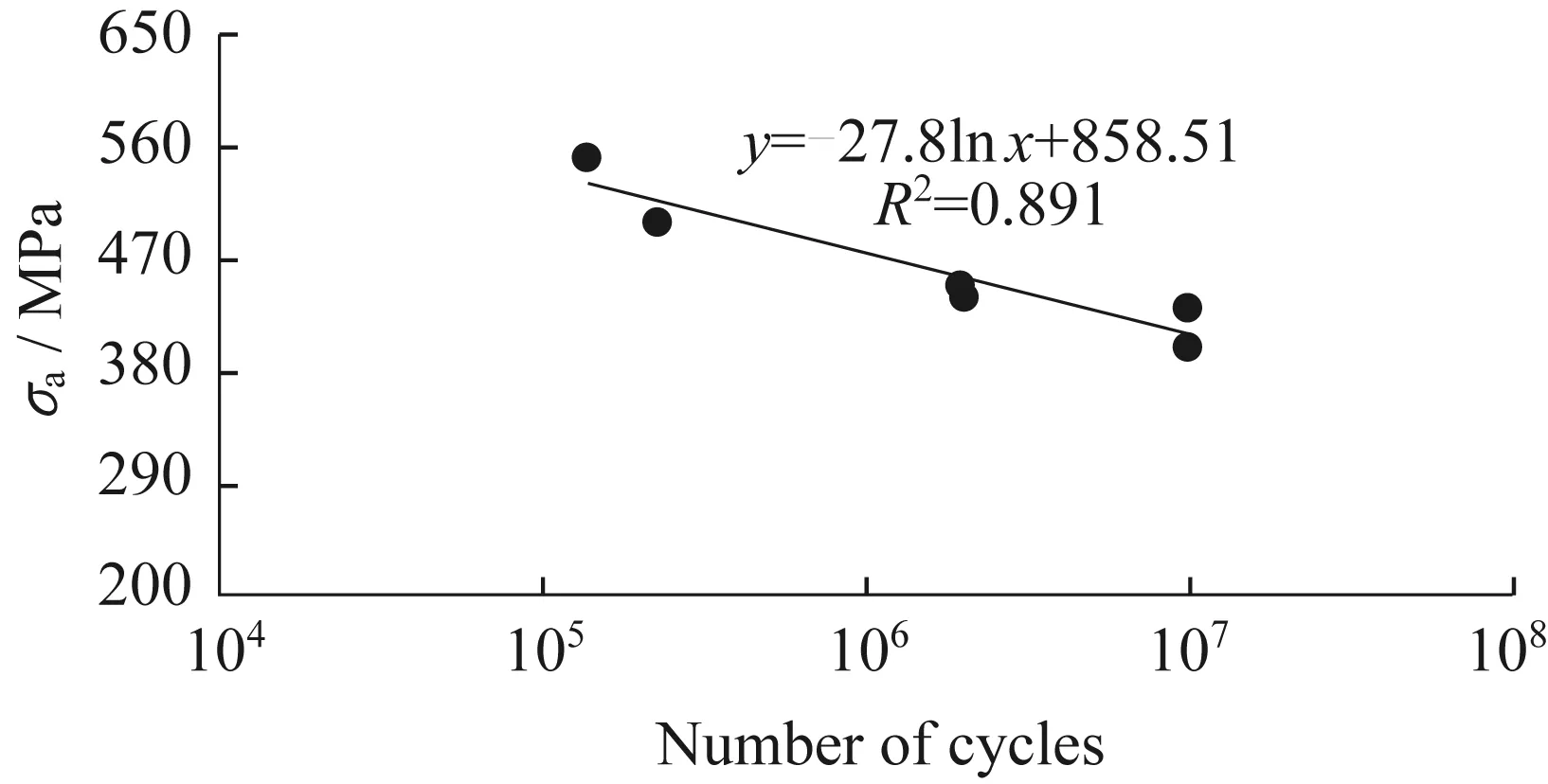

Fatigue properties of materials are important for service.In this study,the fatigue limit has been measured to comprehensively evaluate the perfor-mance of the newly developed 780 MPa high-strength steel sheet with ultra-high HER,and the results are shown in Fig.4.The fatigue limit is 430 MPa,which is higher than the 300 MPa requirement by a customer.The fatigue limit is obtained under a stress ratio ofr=-1 and a cycling number of 107.Therefore,the newly developed 780 MPa high-strength steel sheet also has excellent fatigue pro-perties except for the abovementioned mechanical properties.This finding further indicates the excel-lent comprehensive performance of the newly deve-loped 780 MPa high-strength steel sheet.

Fig.4 Fatigue limit diagram of the newly developed 780 MPa hot-rolled steel sheet

3.5 FLD

The FLD is an important parameter in the field of component forming.Thus,measuring the FLD of the newly developed 780 MPa high-strength steel sheet is necessary.Fig.5 displays the measured FLD results,from which we can see that the minimum principal strain is approximately 0.35.This value is higher than that of conventional 780 MPa high-strength steel,whose minimum principal strain is usually lower than 0.30.Based on the abovemen-tioned properties,we performed practical trial stamping for different complex components,such as the control arm,spring seat,and fuel tank bracket.All these complex components are successfully stamped,which can be attributed to the excellent com-prehensive mechanical properties.

Fig.5 FLD of the newly developed 780 MPa hot-rolled steel sheet

A 780 MPa hot-rolled advanced high-strength steel sheet with high ductility,ultra-high HER,high fatigue limit,and good surface quality has been successfully developed at Baosteel.The microstru-cture,nanoprecipitates,mechanical properties includ-ing tensile properties and HER,fatigue limit,and FLD are investigated to comprehensively evaluate the newly developed 780 MPa advanced high-strength steel sheet.Based on these measurements,we found that the microstructure was composed of nearly full ferrite grains and nanoprecipitates with a size of 5 μm and 4-5 nm,respectively.Systematic bending tests confirm the good bending ability ofR/t=0.2 at 90°.Fatigue limit and FLD higher than those of the conventional 780 MPa high-strength steel sheet are also obtained for the present steel sheet.Practical stamping for some complex com-ponents,for example,the control arm,spring seat,and fuel tank bracket,further verifies the excellent integrated properties of the newly developed 780 MPa advanced high-strength steel sheet.